Premium Lash Extension Glue/Adhesive Supplier Manufacturer. High quality Eyelash Extension Glue Made in Taiwan the best glue facility. Meet Europe REACH standard. Best quality ever. Extra strong Long Lasting lash glue manufacturer, #1 wholesaler in USA.

The best lash extension shampoo primer bonder wholesale price supplier and Private Label Available.

-

How Lash Adhesive Works: The Role of Humidity in Curing

- Understanding Eyelash Glue: Moisture-Activated Bonding Explained

- The Science Behind Lash Adhesives: Why Humidity Matters

- Curing with Confidence: How Humidity Affects Lash Glue Performance

- Low-Humidity Lash Glue: What Makes It Different and Why It Matter

Eyelash glue cures through a chemical reaction triggered by moisture in the air. The higher the humidity, the faster the glue dries. Conversely, in lower humidity environments, the curing process slows down.

To ensure reliable performance even in low humidity conditions, low-humidity adhesives are formulated with trace catalytic agents that help accelerate curing. This is the key difference between low-humidity adhesives and standard formulas.

Generally, low humidity refers to a range of 25%–45%. Adhesives are effective in a wider humidity levels, just the higher the humidity, the faster the glue will cure.

The Curing Mechanism of Eyelash Extension Adhesives

Eyelash extension adhesives are typically based on cyanoacrylate monomers, a class of fast-curing acrylate esters known for their strong adhesion and rapid polymerization. The curing process is fundamentally a moisture-triggered chain reaction, which can be described as follows:

1. Chemical Composition and Reactive Nature

The primary component of lash adhesives is cyanoacrylate (CA), most commonly ethyl cyanoacrylate or butyl cyanoacrylate. These monomers are stabilized in the liquid state by trace acidic inhibitors, which suppress premature polymerization during storage.

In the bottle, cyanoacrylate exists in a metastable equilibrium. Once exposed to moisture in the surrounding air or on the substrate (the natural eyelash), this stability is disrupted, and polymerization is initiated.

2. Moisture-Initiated Anionic Polymerization

The polymerization mechanism of cyanoacrylates is typically anionic chain-growth polymerization, initiated by nucleophiles.

-

Initiation:

CH₂=C(CN)COOR + OH⁻ \;\;\longrightarrow\;\; ⁻CH₂–C^•(CN)COOR

The trace amounts of water (H₂O) in the environment undergo auto-ionization, generating hydroxide ions (OH⁻). These anions attack the electron-deficient carbon atom of the cyanoacrylate double bond (activated by the electron-withdrawing cyano –CN and ester –COOR groups). -

Propagation:

The reactive anionic site propagates rapidly, attacking additional cyanoacrylate monomers. This results in rapid chain growth, producing a linear polymer: -

Termination:

Termination occurs either through protonation (neutralization by acidic species) or by chain transfer reactions. In practice, the polymerization is extremely fast, often reaching full solidification in seconds.

3. Influence of Humidity on Curing Kinetics

Because moisture provides the initiating hydroxide ions, relative humidity (RH) plays a crucial role in curing rate:

-

High Humidity (>65% RH):

Excess water vapor accelerates initiation, leading to overly rapid curing. Adhesive may partially cure before proper bonding occurs, causing weak adhesion, blooming (whitening due to side reactions), and stronger odor emission. -

Low Humidity (<40% RH):

Insufficient water slows down initiation, delaying curing and reducing bonding efficiency. In such cases, specialized formulations with catalytic additives (low-humidity adhesives) or environmental humidification are recommended. -

Optimal Ranges:

-

Standard formulations: 40–65% RH

-

Low-humidity formulations: 25–45% RH

-

4. Role of Surface Chemistry (pH Effects)

Besides environmental humidity, the surface pH of the substrate (eyelash or skin contact area) can significantly influence curing:

-

Alkaline surfaces (higher pH): Provide more nucleophilic sites (OH⁻), accelerating polymerization.

-

Acidic surfaces (lower pH): Neutralize anionic initiators, slowing the curing reaction.

This is why pre-treatment agents (primers) with mild alkalinity are sometimes applied to natural lashes, ensuring consistent curing kinetics.

👉 Practical Note: The effectiveness of lash primers depends on their pH. By testing the pH of a primer, one can determine whether it enhances curing (slightly alkaline, beneficial) or potentially has the opposite effect (too acidic, inhibitory).

5. Practical Implications in Lash Application

-

Fast curing is beneficial for efficient application but may reduce working time for the technician.

-

Slow curing increases risk of poor bonding or lash slippage.

-

Adhesive formulations are therefore engineered with stabilizers, plasticizers, and accelerators to balance curing speed, flexibility, and durability under varying environmental conditions.

✅ In summary:

The curing of eyelash extension adhesives is governed by anionic chain polymerization of cyanoacrylate monomers, initiated by trace environmental moisture. Both humidity and substrate surface pH critically determine the curing kinetics, and adhesive formulations are carefully adjusted to optimize performance across different working environments.

✨ Tip for Checking Your Glue ✨

Once opened, glue cannot be returned or refunded — but don’t worry, it’s very easy to check its freshness before you open it!

Just give the sealed bottle a little shake:

-

If you hear a clear, watery sound, your glue is nice and fresh.

-

If the sound is thicker or less fluid, the glue may have started to age.

- Over time, adhesive naturally becomes more viscous, and the sound will turn softer and less fluid.

We recommend doing this quick “shake test” when you receive your order, so you know your glue is in perfect condition before using it. 💧

💡 Extra Advice: To keep your work at its best, we don’t recommend stocking too much glue at once. Just buy enough for about 1-2 months of use, then reorder when you need more — that way, you’ll always enjoy the freshest adhesive.

👉 Don’t forget: every bottle has its EXP date printed on the bottom, so you can easily check and rotate your stock!

💡 About Storage:

We store all adhesives in large batches at a low temperature (5–10°C) to keep them fresh. But once they arrive to you, storage conditions may be different — meaning the glue’s real shelf life can be shorter than the factory EXP date on the bottle.

👉 That’s also why we recommend: don’t stockpile too many bottles. Just buy enough for 1–2 months of use, then reorder — this way, you’ll always be working with fresh, reliable glue.

How to Store Your Lash Adhesive Correctly

1. Unopened Glue – Long-Term Storage

-

Store in a cool, low-temperature environment (5–10°C / 41–50°F).

-

This slows down the natural aging process of cyanoacrylate and keeps the glue fresh until you are ready to use it.

-

This is how we store glue in bulk at our facility.

2. Opened Glue – After First Use

-

Once opened, do not return the bottle to cold storage.

-

Moving glue between cold and warm environments causes condensation on the bottle walls (like a car windshield fogging up in winter).

-

These tiny water droplets can trigger premature curing inside the bottle, making the glue thick or unusable.

-

Instead, store opened glue at room temperature, ideally 15–20°C (59–68°F), in an air-conditioned or stable indoor environment.

-

Use within 4–6 weeks after opening for best performance.

3. Common Mistakes to Avoid

❌ Storing opened glue in the fridge → condensation and early curing.

❌ Leaving glue in direct sunlight or near heat sources → rapid aging.

❌ Stockpiling too many bottles → risk of expired or thickened glue.

👉 Best Practice: Buy only enough glue for 1–2 months of use, check the EXP date printed on the bottom of each bottle, and restock as needed. This ensures you always work with the freshest adhesive.

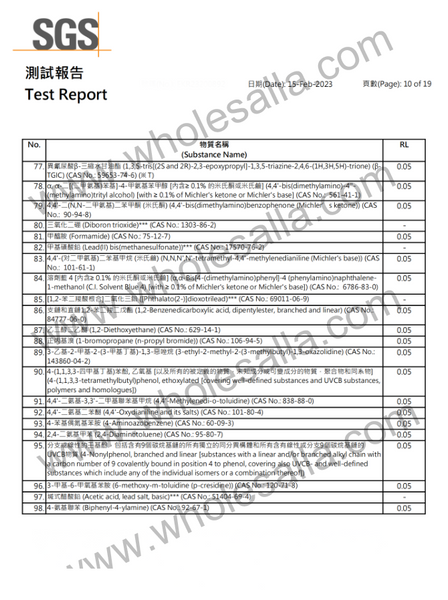

We have the highest quality lash glues which made in Taiwan, and meet Europe standard which is highest standard than other countries. If you want to buy the highest quality glue , please make sure to ask your supplier if the glue meet the Europe Test .

- Superhero (for low to medium humidity) 0.5-1 sec fast dry glue

- Superpower (for normal humidity)0.5-1 sec fast dry glue

- Superpower Invisible 0.5-1 sec fast dry glue

- SuperGentle Glue 1 sec

- Baby Pink glue 0.5-1 sec fast dry glue

- Beginner glue 2sec

********************************

Legal Disclaimer:

★ SAFETY WARNING:

The glue can bond skin and eyes in seconds. Avoid contact with eyes and skin. Keep of the reach of children and pets.

Do not dispense or shake the glue near face or hair, do not put the nozzle of bottle toward anyone's face.

For professional eyelash extension use only.

For external use only. The glue must only be used by trained and certified and insured eyelash technicians.

DO NOT USE THIS PRODUCT FOR SELF APPLICATION!! IT MAY CAUSE EYE IRRITATION AND BURNING.

★ FOR PROFESSIONAL USE ONLY

★ Clients must keep their eyes closed throughout the entire application process

★ The adhesive should never have contact with client's skin and eyes. Make sure the glue does not contact with eyelids.

★ Never try to apply eyelash extensions by yourself

★ Seller is not responsible for any misuse of glue. Buyer understands that for a private label order, all products are unlabeled, and buyer need to properly label products before resale.

★ EYE Contact - Immediately flush eyes with running water for at least 15 minutes

★ If redness, itching or a burning sensation develops, see a physician immediately!!

**********************************

BEST QUALITY EVER

Best quality glue must have the Europe REACH test report.

Opened or used glue is not eligible for return or refund.

It’s very easy to check the glue’s quality before opening.

When you receive the glue, simply shake the bottle—

the clearer and more liquid the sound, the fresher the glue.

As glue ages, it gradually becomes more viscous, and the sound when shaking will become softer or less fluid.

We recommend performing this shake test before opening the bottle to ensure the glue is in optimal condition.

**********************************

Tips:

Our glue is a fast-drying formula that is extremely sensitive to moisture in the air. Even small amounts of humidity can trigger the curing process. That’s why each glue pouch includes a small packet of desiccant to absorb moisture. Please make sure the bottle does not come into contact with water and avoid wiping the nozzle with anything damp.

We offer two main types of glue: one for standard humidity and one for low humidity.

In extremely dry environments, the glue may cure very slowly or seem inactive, as moisture in the air is necessary to trigger the curing process. The low-humidity formula is specially designed to be more sensitive to environmental moisture—meaning even a small amount of humidity is enough to activate the curing reaction. In normal humidity conditions, it cures even faster than the standard humidity formula.

When you receive the glue, you can gently shake the bottle.

- If you hear a clear, watery sound, the glue is in good condition.

- If the sound is faint or sluggish, the glue may have aged. In that case, please do not open the bottle—just send us a video of the shaking test, and we’ll be happy to send a replacement.

Please note: once opened, glue is non-returnable.

If the glue worked well the first time you used it, that confirms the product was in perfect condition. If it later dried out, it’s likely due to storage or handling issues, which are not covered under our return policy.

If the glue seems dry on the second use, it may just be a clogged nozzle. You can shake the bottle to check—if you still hear liquid inside, the glue is fine. Try using a longer pin to gently widen the nozzle opening and allow the glue to flow again.

⚠️ Important reminders:

- ❌ Do not wipe the nozzle with water

- ❌ Do not transfer the glue to another bottle—it will fully cure within hours

- ✅ Always store the glue in the original pouch with the desiccant and seal tightly, or in an airtight container with the desiccant inside

Tips to prevent nozzle clogging:

- When dispensing, hold the bottle nozzle down and quickly squeeze out one drop

- Immediately turn the bottle nozzle upright before releasing pressure

- This helps draw excess glue back into the bottle instead of letting it sit in the nozzle

- Wipe the nozzle clean with a dry tissue, close the cap tightly, and store it in the original pouch with the desiccant, or in an airtight container with the desiccant inside

- If the nozzle isn’t cleaned properly, dried glue can reduce the seal and cause air to enter

If you have any further questions or need assistance, please don’t hesitate to reach out. We’re always happy to help!

**********************************